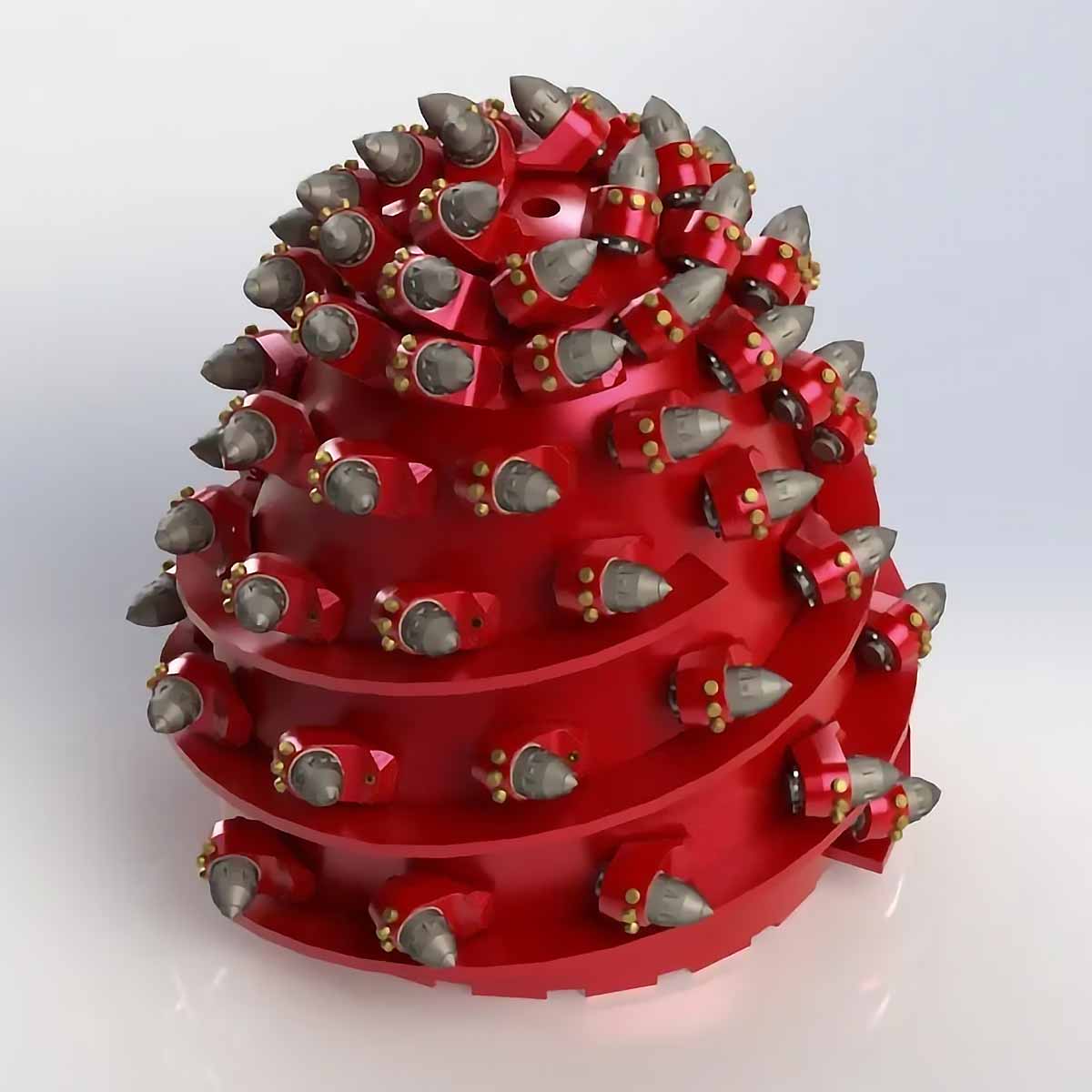

Cutting head manufacturing of the roadheaders EBZ

-

High daily productivity achieved by changing the cutting pattern and compacted setting of cutter holders.

-

Increasing the service life of heads before overhaul repair, which is achieved when surfacing of the Tung Studs system horns on the cutter holders in places subject to the worst abrasive wear.

-

High wear resistance of the cutting tool (up to 20 times higher than the Ukrainian and Russian analogues).

-

Low production costs.

-

Reducing the current load on the motor of the operating member up to 15%.

The best technical and economic performance of the operating member is achieved when using a head equipped with cutter holders and cutters from “BETEK”.